SHORT PATH WIPED FILM EVAPORATORS

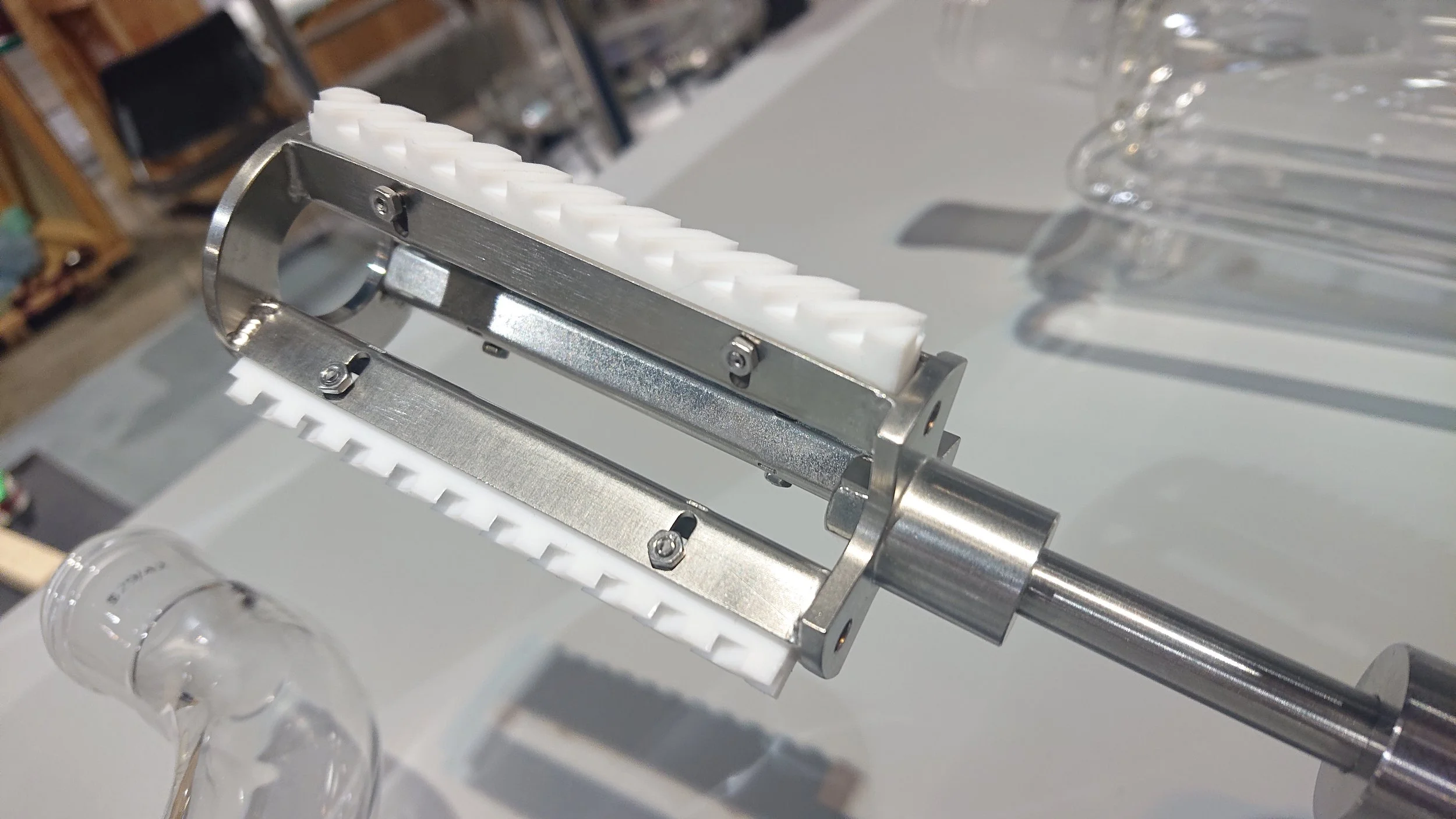

Wiped Film Evaporator (WFE) is an approach to distillation that creates a consistent “thin film” of material along the evaporative surface, maximizing surface area and heat transfer. Grooved wipers or rollers (in PTFE or PBI) are held in a basket spun by an overhead motor. During operation, crude oil is displaced evenly as it presses the heated surface of the jacketed body. The idea is to create the optimum conditions for heat transfer and evaporation so that fine separations and low temperatures distillations are possible.

Sensitive Distillations

Distillations often require temperatures high enough to damage to the target itself or other valuable compounds in the crude feed. However, under rough & fine vacuum (reduced vapor pressure), the boiling points are greatly reduced. Operators are then able to avoid thermal decomposition of their product(s) and often enjoy a significant increase in productivity. With that, the wiping mechanism offers the highest evaporation efficiency, ensuring energy is being used efficiently.

Why a Short Path (SPE)?

Short Path Evaporators (SPE) are a design type of wiped films (WF). What distinguishes this distillation approach is its internal condenser. The idea is to offer the distilled vapor the shortest path from evaporative surface to where it will condense back into a liquid. This results in the shortest path of vapor between distillation & condensation surface.

With that, short path is a uniquely efficient approach to vacuum distillations. However, it relies entirely on the principles heat & vacuum and the advantage of thin film. Because the path is so short, there is no reflux or subsequent distillations on the path to the condenser, like with fractional distillation columns. Separation capabilities perform differently than with a column and this method is often used for bulk purifications of crude oil - think 40% distilling up to 90%+ pure. That being said, the short path allows operators to perform very precise, deep vacuum, low-temperature distillations with a little patience.

Distillates often intentionally incorporate similar chemicals, but require vacuum distillation to protect sensitive compounds, aromas and pigments. SPE is a consistent and continuous solution for producing high-quality, high-value oils efficiently.

Sizes:

.025 to 2m² in borosilicate glass.

0.1 to >5m² in mild steel, stainless, alloys and glass-lined steel.

Process temperature range:

-100 °C to >200 °C

Pressure/vacuum range:

<10^-4 torr to >100psi

Single, double & triple-wall vessels in both glass & steel.

Optimized wall thicknesses, best suited to both insulate the process from the laboratory and affect transfer of energy from the recirculator to the process.

Ring/spiral-baffling for the heat transfer jacket is optional, offering faster processing time & better temperature control.

ASME VIII, Div. 1 U & CE PED pressure & partials available.

Permanent skids or castered, modular systems.

Apical’s short path vacuum wiped films are powerful systems for the production of high-purity oils without the complexity and process time associated with other fractional distillation mechanisms. This is often a good solution for the improvement of an intermediate that will be emulsified, dried or crystallized. The short path between evaporative and condensing surfaces also aids in the separation of near-temperature and sensitive compounds. Apical wants our clients to have the right tools, finding them well-suited for their role and able to offer consistent results for the years ahead.

A1-CWF Shorty Series

The APICAL A1-CWF Shorty series consists of continuous, glass short path wiped film evaporators designed for compliant processing of botanical oils into high-purity distillates under deep vacuum conditions. Operators enjoy the precise control and high throughput while owners rely on the durability, product consistency and protection against contamination Apical systems offer.

Intended to perform low temperature distillations, these systems are workhorses when bulk separations are required. Systems are designed to simplify the production & evaporation of distillate oils, solvents, aromas and so forth. The premise of continuous operation is to make money while you sleep.

The APICAL A1-CWF Shorty series ranges in size from .025m² to 5m² wiped surface area. With throughputs from 250mL/hour to over 25,000mL/hour, Apical has the flexibility to fit systems to your scenario without compromise.

This throughput is backed by your distillate testing over 90% pure. The main body product collects on the internal condenser while low molecular weight compounds like aromatics, terpenes etc. pass to the external condenser. Your heavy molecules don‘t have the chance to distill and are collected after running down the wiped surface.

And, with our systems being built to c/EU-GMP and FDA standards, we remain conscious of OSHA safety guidelines. Apical ensures the safety of your operators with the addition of insulation, warning labels, low pressure heat transfer fluids, shielding and comprehensive training.

Apical has taken years of validated field experience and product trials to develop practical technologies that work every day. We combine academic principles with cutting-edge design to provide equipment that can be relied on for years to come with safe, easy operation, high throughputs and consistent product.

These systems utilize large tubing to ensure an unimpeded vapor path which is critical to maintaining deep vacuum at the process rather than just at the pump.

With that, the internal condenser is sized to carry the full capacity of distilled vapor under the increased efficiency these deeper vacuum conditions allow.

Scaling these dimensions appropriately is key to:

high throughput

consistent purity

equipment lifespan

reduced downtime

efficient commercialization

continuous operation

facility safety

process development

No myths about residence time, degradation or physics, no designs with built-in obsolescence, no exaggerations about system capabilities or pay-to-play obstacles to efficient processing.

Apical has tested a wide range of designs under production settings to pierce the veil and remove the mystique around botanical distillations so business operators can focus on the customer and not a daily headache.

A1-CWF Shorty Series packages include:

Glassware

Centering Rings

Clamping Rings

Lattice Support for Bench-Top

Castered Skid for Kilo & Pilot

Lab Arms & Supports

Insulated Hoses

Stir Motor for Wiper Basket

Ejection Gear Pump(s)

Injection Gear Pump

Heater for Feed Tank & Lines

Heater for Main Body Jacket

Recirculator for Internal Condenser

Chiller for External Condenser

Diaphragm Valve

Vacuum Pump

Vacuum Control

Electric Cold Trap

Apical also provides:

Installation of Complete Systems

Training for Complete Systems

Installation Manual

SDS Sheets

SOP for Operation

On-Going Technical Support

Continuous Systems Built for 24 Hour Operation

Main Body Distillation Rate

250mL to >25,000mL per Hour

Typical Start-up Time

30 Minutes

Typical Runtime

8 Hours

A1-CWF Shorty Series features:

-

Ensure leak-free fitment and ultimate vacuum potential for the system.

-

Grooved PTFE wipers ensure a consistently thin film for maximum evaporation and ultimate control of feed retention time.

-

Baffled to reduce heater duty, balance out temperature distribution of heat transfer fluid and increase condenser capacity.

-

Captures light molecular compounds like terpenes and residual solvents while protecting the pump and reducing maintenance.

-

Retains heat & energy within the system to maximize efficiency while protecting from touch burns per OSHA standards and allowing the operator to see what is happening.

-

Reduces impedance on vapor path which improves vacuum depth and overall throughput.

-

Tubing where hot liquid can potentially pass or collect is vacuum insulated to prevent touch burns.

-

Fitted for deep-vacuum, durability and easy assembly/disassembly, these junctures are fitted with PTFE centering rings & composite clamps.

-

Principle glassware is meant to be permanently installed on the lattice to limit operator interaction.

-

Reflux of common solvents keeps systems looking and performing brand new for years to come.

-

Minority distillates collected on external condensers are sent to batch flasks that can be separated from the system during production.

-

Crude oil is held in a jacketed pre-heat tank before being metered into the system to ensure the highest distillation rates.

-

Distillates can be continuously ejected from the system while in production.