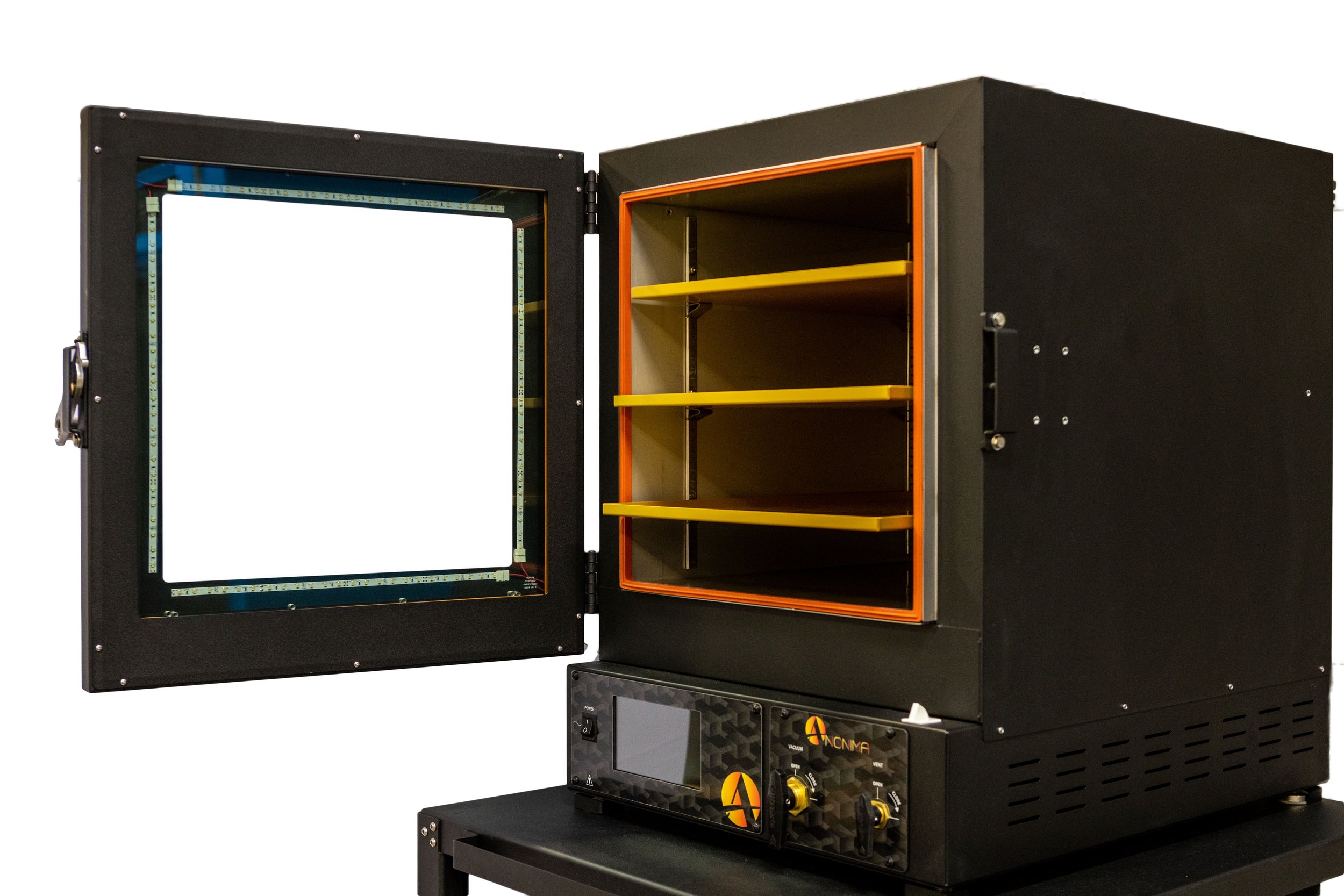

Vacuum Ovens

Batch systems designed to operate at a consistent, stable vacuum & elevated temperatured for a wide range of laboratory processes.

- vacuum drying - decarboxylation - dehydration - environmental testing - biodegradation - curing - baking out

- vacuum drying - decarboxylation - dehydration - environmental testing - biodegradation - curing - baking out

One of the most recognizable items in a R&D and production laboratory is the vacuum oven. A reliable tool for deep drying of product, sorbents and catalysts within a wide range of chemistry. Our system and packages are designed to offer operators consistent performance and product output.

Sizes:

5.0 cubic foot (141 liter)

10.0 cubic foot (282 liter)

UL & CE certified

Temperature range:

Ambient to 150C

+/- 9.0C uniformity (@150C)

+/- 0.2C stability (@150C)

<3 hours to max temperature

Vacuum range:

Rated for 10^-3 torr

25mm vacuum source

Includes 6mm barbs for vacuum vent & inert gas source

Includes:

Up to (8) 18” x 24” shelves

Touchscreen Controller

Over-Temp Protection

Interior Lighting

These systems rely on precise temperature control of the shelves, consistent vacuum environments and reliable monitoring of parameters. Shelves are loaded with aluminum, stainless or glass trays containing the product to be dried. Under vacuum and heat, the product’s residual solvents will evenly evaporate, leaving behind an ultra-pure, safe product.

Other applications include curing/hardening, baking out, biodegradation, dehydration, environmental testing, aging, decarboxylation and more.

Vacuum ovens are able to achieve vacuums well below 1 torr, allowing for the handling of sensitive, low temperature products.

Our complete packages integrate ergonomic carts, terminated tubing, commercial vacuum pumps, diaphragm valves, inert gases and electric cold traps.

Used in a range of industries for decades, the vacuum oven remains a go-to for research & commercial vacuum operations.

Contact us to order!

Standalone ovens starting at $13,999

Turn-key packages starting at $30,000

In-stock or 10 weeks to build.

sales@apical.info

A1-AVO-5 & AVO-10 Series

The APICAL A1-ANONIMA series presents commercial vacuum oven technology for compliant processing of bulk solvents under vacuum conditions. Operators enjoy the precise control and high throughput while owners rely on the durability, product consistency and protection against contamination Apical systems offer.

Our systems are built to meet or exceed c/EU-GMP and FDA standards when called for and we remain conscious of OSHA safety guidelines. Apical ensures the safety of your operators with the addition of insulation, warning labels, shielding and comprehensive training.

All ancillary tubing, fittings, pumps and traps have been tested & sized appropriatedly.

Apical has taken years of validated field experience and product trials to develop practical technologies that work every day. We combine academic principles with cutting-edge design to provide equipment that can be relied on for years to come with safe, easy operation, high throughputs and consistent product.

These systems utilize large tubing to ensure an unimpeded vapor path which is critical to maintaining deep vacuum at the process rather than just at the pump.

With that, light, volatilized vapors are conveniently trapped along the vacuum path by carboy & electric cold trap systems.

No myths about residence time, degradation or physics, no designs with built-in obsolescence, no exaggerations about system capabilities or pay-to-play obstacles to efficient processing.

Apical has tested a wide range of designs under production settings to pierce the veil and remove the mystique around laboratory processes so business operators can focus on the customer and not a daily headache.

APICAL AVO Series packages can include:

3-8 Aluminum or Stainless Shelves

Inert Gas Injection & Generation

-50 & -100C Electric Cold Traps

Deep-Vacuum Isolation Valves

Vacuum Tubing & Fittings

Castered Skid/Cart

Dry & Oiled Vacuum Pumps

Circular Chart Recorder

Multi-System Vacuum Manifold

Stainless or Glass Trays

110V – 120V / 1ph / 14A 50/60Hz

or

220V – 240V / 1ph / 7A 50/60Hz

Apical also provides:

Installation of Complete Systems

Training for Complete Systems

Installation Manual

IQ/OQ/PQ

SOP for Operation

On-Going Technical Support

APICAL AVO Series features:

-

Ensure leak-free fitment and ultimate vacuum potential for the system.

-

Ensures a good joint seal, system longevity and high-purity.

-

Options for -50 & -100C cold traps with integrated, glass, high-capacity vessels specifically for low boiling point vapors.

-

Rotary Vane, Double-Diaphragm and Dry Scroll pump options cover the full range of budgets, depths, CFM flow and uptime potential.

-

Reduces impedance on vapor path which improves vacuum depth and overall throughput.

-

Safety is the #1 priority for operational, preventing staff from touch burns, discomfort and droppage.

-

Fitted for deep-vacuum, durability and easy assembly/disassembly, these junctures are fitted with PTFE centering rings & composite or stainless clamps.

-

Resilient materials and IP-rated electronics allow for simple spray & wipe-down cleaning procedures with common solvents & cleaning agents.

-

Exterior -

26.6” x 38.7” x 33.2”

676 x 983 x 844 mm

Interior -

18.1” x 24.1” x 18.1”

459 x 612 x 459 mm

-

2 Year Limited Warranty